In study, development and research, prototypes enjoy a huge role. These produced prototypes help to do tests prior to creation and assistance to pinpoint the possible conditions that are happening due to the design flaws. Previously creating a prototype version was really pricey process and also time taking. But through the help of Personal computer Numerically Managed CNC Machining, the rate in which a prototype is produced has risen. With Rapid Prototyping, this time around time period has even lowered from few days to several hours.

Rapid Prototyping is surely an additive producing process that produces one of any object from a CAD version because they build it in tears. For this computerized devices are used that develops a three-dimensional style of a throwing coming from a CAD sketching. There are actually different forms of Rapid Prototyping offered based on the needs. One can differentiate between them with the approaches these techniques employ to help make the levels. Adhering to are few of the main forms of Rapid Prototyping:

Stereolithography SLA

Stereolithography employs UV ray to solidify liquefied acrylic polymer level by level with a relocating program and soon after several layers, the prototype in the preferred form is formed. This procedure is carried on within a VAT, a system that may be completing with photo curable fluid acryl ate polymer. Stereolithography is among the most employed sorts of 3d printing as a result of reliability Tolerances= .0125mm, less time considered is dependent upon the size and problem from the portion and exactly where components data is great in addition to their geometry is too hard to machined.

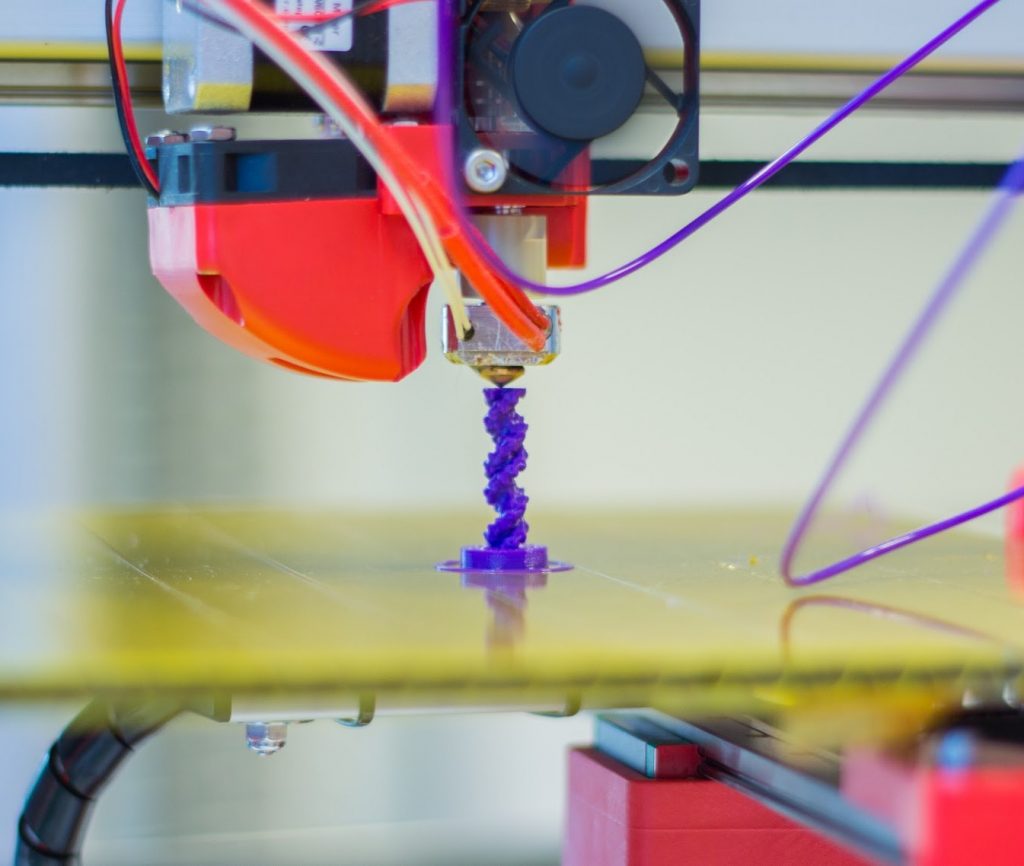

Fused Deposition Modeling FDM

Fused deposition modeling also known as FDM, is really a speedy prototype technological innovation widely used to convert CAD drawings into physical pieces. FDM is really a hallmark of Stratus’s and was created by S. Scott Crump.

FDM functions upon an additive theory which extrudes substance in tears. Plastic material or wax is dissolved and liquefied from the extrusion mind and extruded via a nozzle. The nozzle is created to maneuver more than a path recognized by the CAD style to produce component. Using this method one covering is extruded and then it is lowered to extrude the following covering on top of the first until the entire prototype is constructed, with 1 coating at the same time.

Discerning Laser beam Sintering SLS

Discerning Laser light Sintering employs the key of sintering. Sintering is actually a heating system method that helps prevent melting and a coherent bulk is generated. In SLS, metallic or non-metal powders are sintered utilizing a CAD software led laser light that selectively fuses the powder fabric.

You will find number of far more kinds of Rapid Prototyping offered, like; Laminated Item Producing, 3D Printing, Solid Bottom Curing, Visual Production and Photochemical Machining. Rapid prototyping has provided makers with several positive aspects. Creative designers may look their pieces and in circumstance any fault comes about they may effortlessly remedy it. Apart from industrial use they already have formed part of make. This growth method supplies empty patters to be used in throwing. RP has proliferated biomedical technology.