The majority of people you speak with in your own life will never have even been aware of the term CNC machining well before. Little do they know that the CNC method has most likely handled their life in one way or another. If you work in production it really is more inclined which you have heard of the term and you’ll most likely be getting through a CNC at some point. Everything that an user has the capacity to use conventional unit instruments is programmable using a CNC machine. After that we consider a closer look at CNC machines and their operations.

The reason why CNC resources are extremely efficient is because of their accuracy and reliability, efficiency and productiveness. A CNC machine is pretty easy to take care of and jogging with first set up. Even the function item reloading procedure continues to be programmed in many companies. Most of the time Plastic machining service operators must full other duties linked to the procedures of the CNC. A few of these activities involve measuring function pieces and producing adjustments to maintain the machine jogging at optimum efficiency.

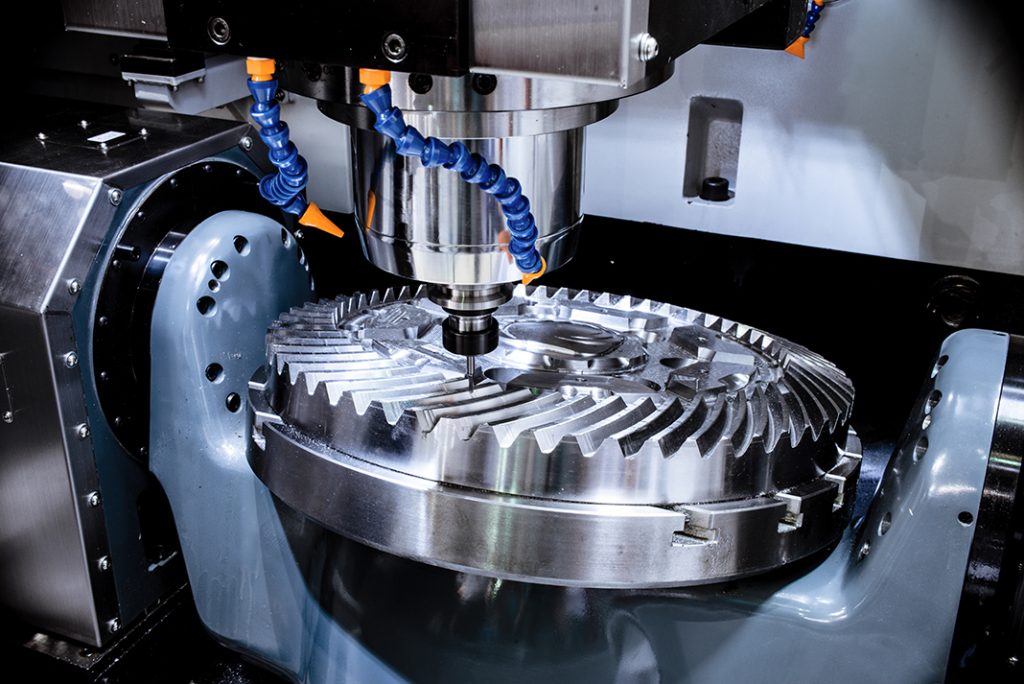

If your CNC could only transfer a function piece in two directional axes its functionality would be significantly limited. For this reason almost all CNC machines are programmed to function in a few other methods. The actual device kind has to do with its programmable components too. A number of these add-ons are the pursuing. A computerized tool changer allows the resource to get immediately placed into the spindle when machining. The speed in the spindle may be easily specific as well as the spindle may be transformed in two recommendations. Furthermore many machining operations need to have coolant for lubrication reasons.

With CNC pressing so many areas of developing and big manufacturing, numerous machining functions now include the application of CNC. We currently have a look at how CNC machining impacts the industry of metal eradication and metallic production. When getting rid of steel the functions of facing, boring, turning, grooving, knurling, and threading are completed with CNC transforming facilities. There are numerous different versions of the models that include, CNC milling equipment, CNC drill and tap facilities, and CNC lathes. Outdoors diameter mincing and interior diameter milling can be completed on CNC grinders.

When you use CNC in association to metal fabrication, visualize a aluminium submitting case. Each of the preliminary elements is made of metal bedding. These sheets are sheared to some particular dimension and slots are positioned in specific locations. The bedding is then created with their last forms. Numerous CNC-like treatments are now useful for processes that explain a series of moves and operations. A few of these include laser cutting, welding, friction mix welding, ultrasonic welding, plasma cutting, forming, material decreasing, routing and also sawing.